PlasmaCLEANER

PlasmaCLEANER Applications :

- Surface cleaning and preheating of copper alloy wire prior to extrusion / cladding

- Acid-free removal of wax protection coating

- Super conductor surface cleaning at temperatures between 200ºC - 400ºC

PlasmaCLEANER Benefits :

When compared to the traditional process of acid cleaning, PlasmaCLEANER offers the following benefits:- Outstanding surface cleanliness

- Effective alternative to pickling, chemical cleaning or electrochemical polishing

- No loss of base material, unlike acid pickling

- Small and compact unit: length 1m – 7m, subject to application

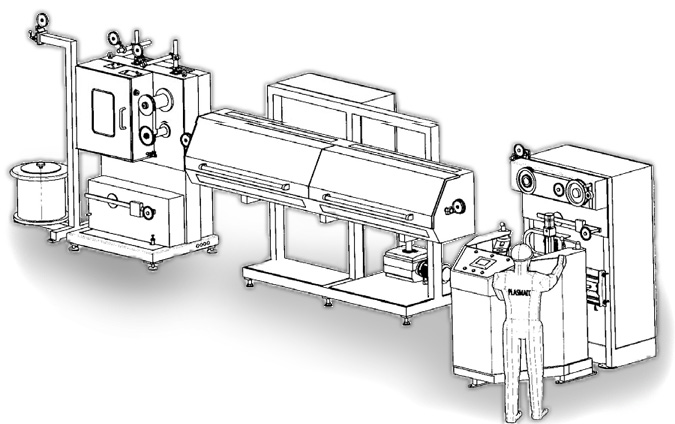

- Can be installed in-line with drawing, plating, cladding or extrusion machine

- Can be used for degreasing and pre-heating when used inline with extrusion or cladding

- Improved adhesion of extruded coating through clean surface and surface activation

- Low operations and maintenance costs

Line Configuration Examples :

- Inline with drawing or extrusion

- Inline with Cladding