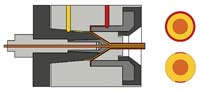

Fluoro-polymer Extrusion Crossheads

Fluoro-polymer insulation crossheads are designed for the high temperature processing required for

these compounds. The crossheads are manufactured using a proprietary UNALLOY™ material that is highly

corrosion and heat resistant due to its special composition and heat treatment.

USCC-F: Fluoro-polymer Extrusion Crossheads

- Stripe or skin with specific program insert/tool

- Highly durable and abrasion resistant steel alloy

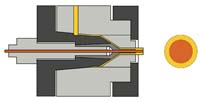

- Torpedo style distribution cartridge

- Quick 3 step tool changes

- Even temperature control

- Skin-Foam-Skin applications

- Units for insulation OD up to 100 mm (3.9")

- Fixed (S) or Manual (MC) centering models

Models – Layer configurations

- SL – Single layer extrusion

- SV – Single layer + stripe/skin

Fixed Center Crossheads

- Immediate precise start-up

- No set-up required

- Immediate concentric insulation

- No operator set-up required

- Reduced scrap

|

|